Case Study:Kstar Empowers ARSC with High-Reliability Prefabricated Modular Data Center

Aerial Photogrammetry and Remote Sensing Group Co., LTD (ARSC) was established in 1965. It is the only bureau engaged in the research, development and application of space and earth information technology in the national coal trade. The scope of services includes aerial photography, digital surveying and mapping, remote sensing application and research, GIS development, and architectural decoration, etc.

Project Background:

Based on massive data, the company planned to use IoT, cloud computing and AI to revitalize data resources. Therefore, it is necessary to build a big data center to store the data and improve analysis efficiency, such as shortening the processing time of 3D models. "After the project is finished, the processing capacity of 600 square kilometers of 3D models in Xi'an can be reduced from the original 290 days to 20 days.'’The company said.

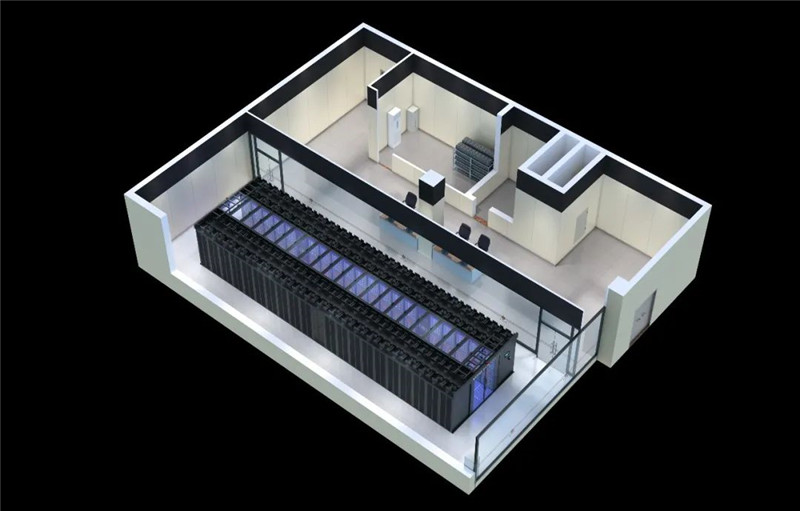

The new data center covers an area of 2,300 square meters and consists of a computer room, a demonstration hall, a preface hall and a technology exhibition hall. It was designed to have 40 service. To ensure high reliability and easy expansion, the company expected to build a prefabricated modular data center. After thoroughly considering lower TCO, quick deployment, easy capacity expansion, energy conservation, and other important features, the company chose Kstar's prefabricated modular data center solution.

Solution

Kstar IDM prefabricated modular data centre solution was used to build the new data center for the company. The solution consists of 40 cabinets, equipped with dual-row cold aisle. As this modular data center is prefabricated in the factory, local construction engineers only needed to carry out simple on-site installation, and it can be put into use quickly.

Benefits

Safe and Reliable:

The enclosed structure of the modular data center solution can protect the facilities from water and dust. All basic infrastructures of the modular data center solution are self-produced. For this project, it can shorten the lead time and reduce after-sales service problems as well.

What's more, the N+1/2N design and smart monitoring system enhance the reliability of the system. Kstar DCMS(data center monitoring system)has a multi-level automatic alarm function and supports remote control and reliable management.

High-Efficiency:

The solution adopts a variable frequency energy-saving row-level of air conditioner in-column layout to eliminate local hot spots, enhancing the bearing load capacity of the single IT cabinet and isolate cold and hot air as well as decreasing energy consumption.

Simplified O&M:

Kstar data center solution chooses fully modular UPS to reduce TCO. All functional modules can be hot-swapped, simplifying Operations and Maintenance (O&M). Indeed, O&M is so easy that basic-level engineers can quickly correct the UPS within five minutes of any fault occurring. Online capacity expansion is also supported, significantly reducing Capital Expenditure (CAPEX) and saving on initial investment required.

It has been 6 months since the completion of the big data center. The solution has not only helped the company achieve its initial objective — to deploy a data center with lower TCO, quick deployment and easy capacity expansion, but also helped the company to achieve stable and efficient operations with O&M greatly simplified as well.

Learn more about Kstar Prefabricated Modular Data Center Solutions>