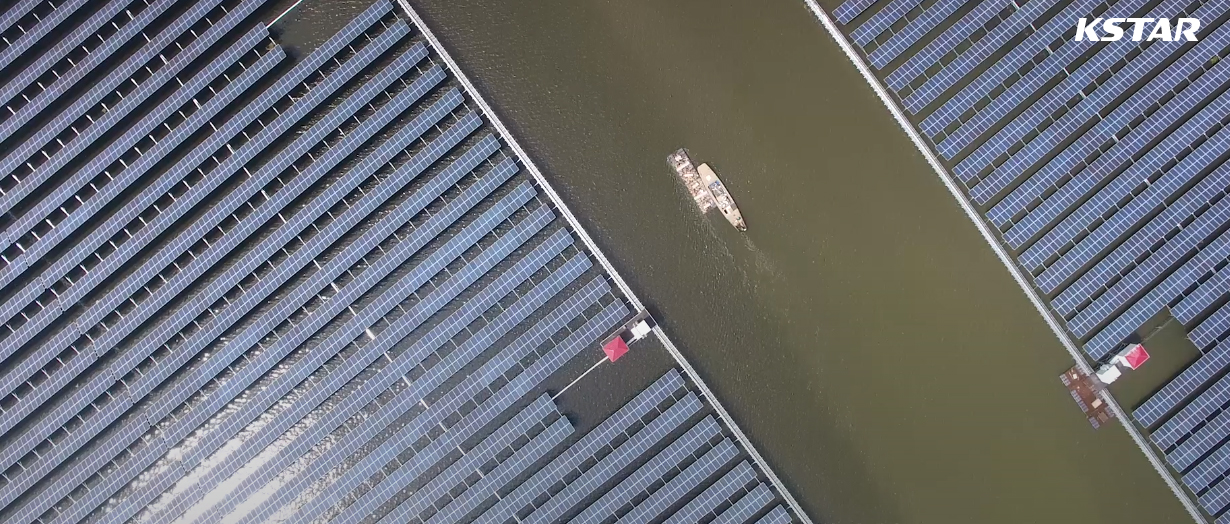

KSTAR 320MW Solar-water Power Plant

April 17, 2020--Shenzhen Kstar Science&Technology Co.Ltd., the global leading smart inverter solution supplier for new energy, announced that the company’s central inverter (GSL2500C-MV and GSL1250,high efficiency up to 99% ) solutions,which are well grid-connected into the 120MW solar-water power plant,the second phase of a 320 MW project at Cixi city, Zhejiang province,China.The power plant starts to generate electricity since Dec 30,2019,whose subsidy is 0.095 RMB kwh and the total investment of the second Phase is 100 million USD.

For the phase I of the big project (FIT is 0.85 RMB), it is 200MW installation with a total investment 250 million USD at Zhouxiang reservoirs in Cixi. The plant has been operational stably and safely for more than three years at a solar-water Power Park, and it is the largest solar-water park in China.

The challenges there were at Zhouxiang reservoirs in Cixi:

1) Easy to get foggy (salt fog)and wet air, the equipment should have strong anti-corrosion ability

2) The construction cost of power station is large, so the cost of inverters and system should be reasonable and cost-effective.

3) High temperature and high humidity.

4) Operation and maintenance were difficult and the cost was high.

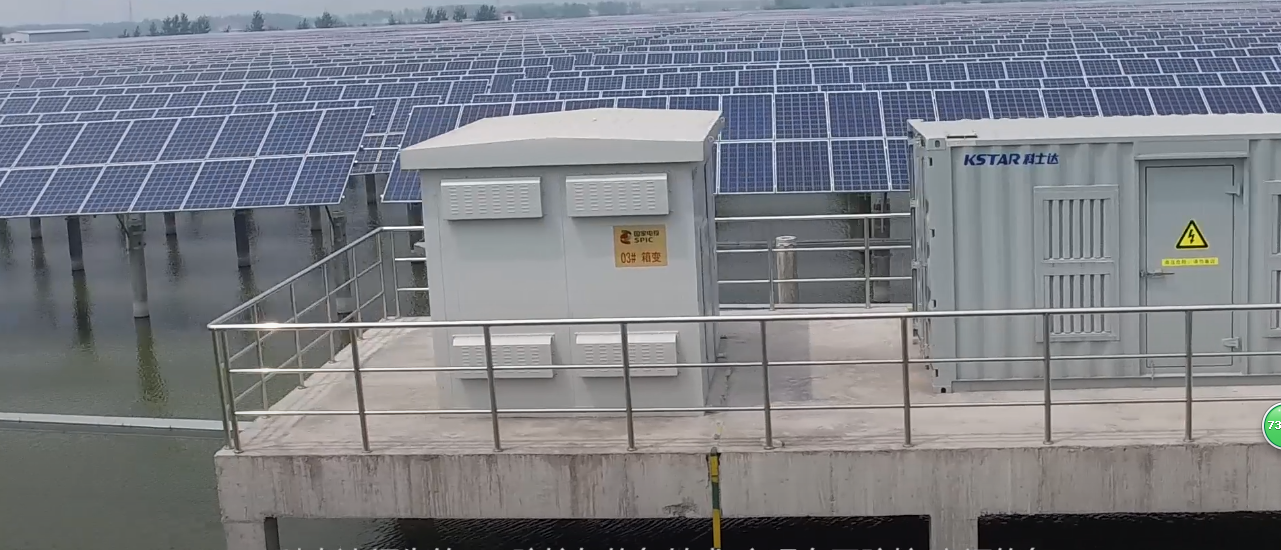

To overcome those challenges and boost the local economy development and save land resources, the 320MW (120MW+200MW ) solar-water power plant at the reservoirs has been installed and operated successfully in Cixi,China, where the PV central inverters are all provided by KSTAR. All of the KSTAR inverters GSL2500C-MV and GSL1250 are equipped against humidity,which are quite safe, reliable and high efficiency.The inverters have protects against dirt and moisture. IP54 guarantees the protection against corrosion in high humidity and high salt fog environment. Therefore, The PV power plant on a body of water has a high power generation efficiency,and brings low operations and maintenance costs as well as a minimal impact on the maritime life.

The 320MW (120MW+200MW ) solar-water power plant has been completely grid-connected with an expected annual generation of 352 million KWH. It is the largest solar-water PV plant in China, which all the electricity is connected into the State Grid Corporation of China,greatly reducing the pressure of local power grid operation,making environment much greener by utilizing renewable energy.The power plant can save 100,000 tuns of coal annually, and reduces 189,200 tons of carbon dioxide and 14.32 million tons of sulfur dioxide. The annual electricity revenue of the owner is about 45 million USD, and the annual fishery income can reach nearly 5 million USD.

The Zhouxiang reservoirs at Cixi are very large with fishes and shrimp farming ,covering nearly 300 hectares, and the widen surface is very suitable for the installation of large-scale solar power plant. Near the reservoirs, the transportation is very convenient. Besides,the area is located in the subtropical region with a monsoon climate.The annual average temperature is 16.0℃,and the highest of the average is 28.2 in July,℃, the lowest temperature is 3.8℃.There is sufficient rainfall, with an annual average rainfall of 1272.8mm. The peak month of precipitation is September, accounting for an average of 14% of the annual rainfall. The environment is a challenge for PV manufacturers, but for KSTAR, its flexible turnkey solutions provide higher yields, safety and reliability for the whole project. The operating temperature range of the inverters is –40℃~+60℃(More than 50℃ derating).

KSTAR central inverter greatly shortens construction period and saves operation cost, but also has great advantages in post-operation and maintenance, anti-corrosion capacity, smart anti-PID solutions.There are four big advantages for KSTAR PV solution for central inverters:

1.Low cost in Investment and the system maintenance.

The solutions integrate high-efficiency booster transformer,medium-voltage distribution and monitoring system to save system cost.

Integral hoisting reduces the construction difficulty and shortens the construction period. The inverter and transformer is unified maintenance & construction,thus users are no worries.The transformer can be customized, flexible to cope with a variety of application scenarios.

2. Excellent natural cooling design

The method for heat-dissipation is forced air cooling, with a vertically designed duct. Air extraction is handled by the power module. Heat dissipation from the air duct of the inverter is designed to be isolated from that of the magnetic unit (reactor). The fan is controlled intelligently and can only be started when a maximum temperature has been reached.

3.Strong corrosion resistance

IP54 meets the application conditions of the power station on the water, and guarantee the protection against corrosion in high humidity and high salt fog environment.

4.Strong protection and maintenance capability

KSTAR’s inverters are featuring PID protection,which can effectively prevent PID attenuation of components and ensure the performance of components and power generation of the station.Customers are no need to worry that the components will be corrosion in wet and high temperature. KSTAR’s turnkey solutions with central inverters installed is flexible and strong adaptability. Moreover, the solar-water power plant does not affect the civil construction, but help the customer to reduce the investment cost, speed up the project’s completion, and ultimately achieve the maximum revenue for the owners.Besides,that greatly reduce water surface evaporation and save water resources,also creating a better hatching environment for fish and increase aquatic production.

“ It is a pleasure that we supply the intelligent turnkey solutions for the big project. We are encouraged by the fact that the products have received wide attention and recognition from our industry customers, colleagues, and media. As time flies, the 320MW (120MW+200MW ) solar-water power plant is operated successfully,and we do a great job for the customers. We will continue to work hard to meet growing demands of our old and new customers.,” said Gary Ye, the Vice-GM of Shenzhen Kstar Science&Technology Co.,Ltd.